Next: The Process. Once your epoxy floor is applied, it will give you years of tireless service, assuming you get it right. Once you’ve mixed your epoxy components, you will have a limited time to apply your coating. Again, you need to check the product label, which should give you an idea of how long you have to complete the application after mixing the epoxy.

Not All Epoxies Are Created Equally: When Is Epoxy Not Epoxy?

It will come as no surprise to you when we say we love epoxy coating as a floor covering. It’s tough, easy to care for, and stylish enough to use inside your home, office or showroom. And don’t get us started on how good it looks outdoors, whatever the weather.

But like any high-quality, highly desirable product, there are plenty of impersonators, and while they may claim to be “just as good, only cheaper”, they come with their share of pitfalls.

What is a true epoxy coating?

The term “epoxy” denotes the materials used, and by implication, the application process. A true epoxy coating includes a resin component that is mixed with a hardener, then applied under specific conditions – temperature and time being the most critical. (Think of mixing Araldite – once mixed, the components need to be applied quickly and accurately for the adhesive to do its job.)

While there are products out there that call themselves epoxy “paint”, this is more of a consumer-focused name – people associate the application with painting, and so hardware suppliers use the term to help their customers find the product more easily. Unfortunately, this does nothing to clear up the confusion of what is a true epoxy finish.

What is epoxy paint?

Also referred to as one-part epoxy, as it doesn’t require the mixing process of a true epoxy coating. What is termed epoxy paint is a paint product – usually an acrylic or latex base – with some epoxy in the mix. While it is more durable than standard acrylic paint, it doesn’t have the resilience of a true epoxy coating.

Epoxy paint doesn’t need any special application, other than a roller or paint brush and is usually just given a single coat. While that may be a much easier option than laying an epoxy coating, it will start to show signs of wear after a relatively short time.

If the surface beneath is stained or hasn’t been properly prepared, large chunks of paint can start to chip off. Whether you’ve invested the time to do the work yourself, or paid a contractor, seeing this deterioration so soon – it can start cracking and flaking after only a few months in high traffic areas – it’s no less a disheartening and disappointing sight. Not to mention a deceptively false economy, as it will need regular replacing.

A true epoxy floor coating involves a lot of preparation – a process you may forget once the floor is down, but one that will perform and last for years to come. Where an epoxy paint might stain, crack, chip or wear; an epoxy coating is highly resistant to all of these degraders. It is by no means invulnerable, but its’ hardwearing, easy-care features make it highly attractive – in both form and function – for a wide range of applications.

11 Acrylic Resin Paint Manufacturers in 2023

This section provides an overview for acrylic resin paints as well as their applications and principles. Also, please take a look at the list of 11 acrylic resin paint manufacturers and their company rankings. Here are the top-ranked acrylic resin paint companies as of November, 2023: 1.ChemPoint, 2.Copps Industries, Inc., 3.Allnex GMBH.

Table of Contents

- What Is an Acrylic Resin Paint?

- List of 11 Acrylic Resin Paint Manufacturers

What Is an Acrylic Resin Paint?

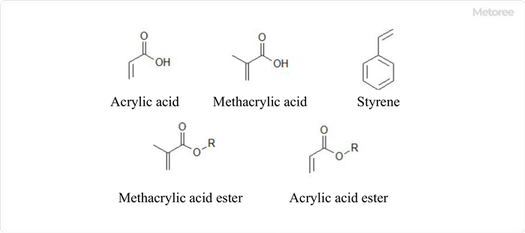

Acrylic resin paint is a term for paints made primarily of acrylic resin, originating around 1950. Acrylic resin is co-polymerized from acrylic acid, methacrylic acid, their esters, styrene, and other monomers, and is used in a wide range of applications such as adhesives and organic glass, in addition to paints, due to its high degree of freedom in molecular design.

Figure 1. Typical monomers that make up acrylic resins

When acrylic resin paint was first marketed, it quickly became popular due to its excellent color and gloss, but today, urethane and acrylic silicone resin paints with higher performance are the mainstream. Due to volatile organic compound (VOC) issues, solvent-based paints are being replaced by water-based paints.

Uses of Acrylic Resin Paints

The main applications of acrylic resin paints include exterior wall painting and DIY. Although the use of acrylic resin paints has been decreasing due to the spread of urethane resin paints, acrylic resin paints are still widely used for the top coat of concrete, mortar, roof tiles, PC concrete, and other surfaces on building exteriors and interiors.

Acrylic resin paints are also often used for furniture and DIY projects because of the wide variety of colors available. Acrylic resins have a wide range of uses because their physical properties can be changed according to application, from flexible to hard coating films, by adjusting the type of monomer and degree of polymerization.

Types of Acrylic Resin Paints

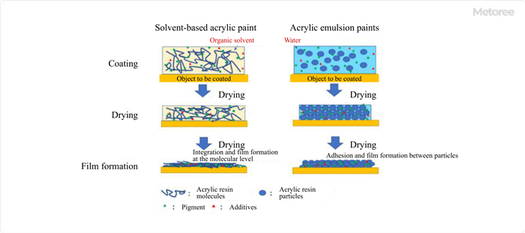

Figure 2. Different mechanisms of acrylic resin paint film formation

There are two types of acrylic resin paints: oil-based solvent-based acrylic paints and water-based acrylic emulsion paints.

1. Solvent-Type Acrylic Paints

Solvent-type acrylic paints are paints in which acrylic resin is dissolved in thinner, a solvent. Since paint film formation occurs at the molecular level, they have excellent weather, water, alkali, and oil resistance. The biggest disadvantages of solvent-based acrylic paints are the smell of thinner and toxic substances.

Since the main purpose of use is construction, consideration must be given to the surroundings. In addition, protective measures are required not only for the surroundings but also for the workers who handle the paint.

2. Acrylic Emulsion Paint

Acrylic emulsion paints, also called waterborne acrylic resin paints, are paints made by emulsifying and dispersing acrylic resin in water. As with solvent-based acrylic paints, it is possible to design functions. Recently, paints with improved functionality have been developed by including additives such as antiseptic, antifoaming, antifungal, and antifouling agents.

Since acrylic emulsion paints do not use solvents, they are virtually free of odors and damage caused by toxic substances. The ever-increasing functionality provided by additives has led to more and more paints being adopted for the same architectural use.

Other Information on Acrylic Resin Paints

1. Advantages and Disadvantages of Acrylic Resin Paints

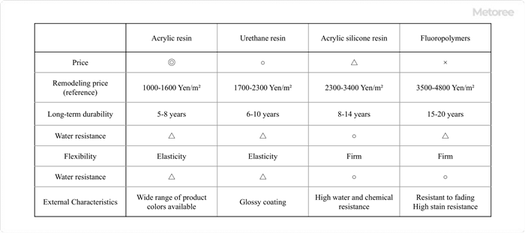

Figure 3. Comparison of characteristics of various paints

The advantages of acrylic resin paints include low cost, good color and gloss, a wide variety of colors, easy handling by amateurs, and ease of layering. On the other hand, one disadvantage is that they are susceptible to ultraviolet rays and deteriorate quickly. The biggest reason for the sharp decline in demand is due to its weak resistance to UV rays and other weathering factors.

In addition, plasticizers are blended to make the coating film flexible, but the plasticizers are gradually reduced by heat and ultraviolet rays, causing the coating film to harden and crack. The service life of acrylic resin paints is short, ranging from 5 to 8 years, and acrylic silicone resin paint, which has a longer service life, has become the mainstream.

Acrylic silicone resin is an acrylic resin with a silicone skeleton introduced into the molecule. This reduces the disadvantages of acrylic resins. For this reason, acrylic silicone resin paints are often used in paints for residential exteriors.

2. Acrylic Resin Paint Manufacturing Process

In general, paints are manufactured through a five-step process. Acrylic emulsion paints require more dispersants and other additives than solvent-based acrylic paints because more particles are dispersed in acrylic emulsion paints. In addition, reactive cross-linking agents are sometimes added as raw materials to increase coating film strength.

- Pre-kneading

Resins, pigments, surfactants, and solvents are mixed to produce a particle dispersion (mill base). - Dispersion

The mill base is dispersed in a dispersing machine until uniform. - Mixing

Additives and other ingredients are added to the dispersed mill base to improve the performance of the paint. - Filtration

Paint is finished by filtration to remove foreign substances. - Coloring

Colored paints are mixed with the finished paint to add color. After coloring, each container is filled and shipped.

3. Characteristics of Acrylic Resin Baking Coating

Acrylic resin baking coating is a coating method in which acrylic resin paints are applied to an object and then the object is heated to thermoset the acrylic resin, dramatically increasing the strength of the coating film. In the case of acrylic resin, heating and drying at a high temperature of 140°C to 180°C for 20 to 30 minutes is required. Baking coating increases hardness, scratch resistance, and adhesion of the coating film.

Since baked coating increases weather resistance, it decreases degradation, fading, and chalking caused by ultraviolet rays, which have been weak points of acrylic resins. However, the disadvantage of this tough coating is that it has a weakness in flexibility and cracking. Therefore, baked-on acrylic resin coating is suitable for outdoor products.

Other applications include indoor and outdoor furniture and wall coatings, as well as the painting of small parts due to its special characteristics. The most familiar examples are vending machines that require weather resistance and accessories that require colored paints.

Baking coating can enhance the functionality of acrylic resin beyond its original performance, but it requires high temperature and long baking time, so there are restrictions on the heat resistance temperature of the object to be coated and its size.

List of 11 Acrylic Resin Paint Manufacturers

*Including some distributors, etc.

Sort by Features

- Default

- Company Size: largest first

- Year Founded: oldest first

- Year Founded: earliest first